You can make biogas energy with a DIY methane generator.

Producing methane from manure using your own small scale waste to energy biogas digester is feasible for many small farms.

What is Biogas Energy?

Biogas energy is fueled by burning methane produced by the decomposition of organic wastes.

Methane is a gas chemically CH4. It is colourless, odourless and, of course, flammable. Methane is widely used as the main constituent of mains natural gas.

Whenever organic materials are decomposed by bacteria anaerobically (i.e. in the absence of oxygen) methane and carbon dioxide are produced.

Sources of Biogas Energy

Just about any organic waste can be decomposed as a methane generator – plant (soft material is better than woody material) and animal wastes, and even human waste.

On a municipal level, rubbish tips act as biogas digesters and are prodigious methane generators. Even in Perth, Australia, companies are actively harvesting this methane to produce climate friendly biogas electricity.

In fact, because un-burnt methane released into the atmosphere is a powerful greenhouse gas, 10% of our personal impact on the climate comes from the food refuse we put in our garbage bins that ends up decomposing under landfill.

In a small scale waste to energy situation it is possible to generate methane from manure or even sewerage. And biogas energy is constantly being manufactured in digestive systems like yours and your cow’s… yes, farts are methane too!

Pros and Cons of Methane Generator Systems

Advantages

Makes good use of organic wastes. You can obtain fuel from sewage sludge and animal slurries first, and prevent runoff and methane emissions at the same time and you still get fertiliser at the end of the process.

Is a clean, easily controlled source of renewable energy.

Uses up methane, a powerful greenhouse gas.

Reduces pathogen (disease agent) levels in the waste.

Residue provides valuable organic fertilizer.

Simple to build and operate.

Low maintenance requirements.

Can be efficiently used to run cooking, heating, gas lighting, absorption refrigerators and gas powered engines.

No smell (unless there’s a leak, which you’d want to know about and fix immediately anyway!).

Disadvantages

Most practical to be generated and used at the source of the waste. This is because the energy needed to compress the gas for transport, or convert it into electricity is excessive, reducing the efficiency of biogas energy production.

For safety, basic precautions (see below) must be adhered to.

Small Scale Waste to Energy Methane Generator Systems

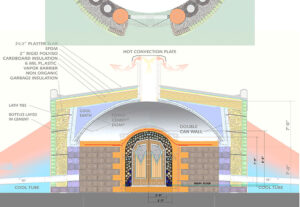

Biogas Energy

Biogas Energy

Each kilogram of biodegradable material yields around 0.4 m (400l) of gas.

So in practice, in small scale waste to energy systems, if you have some livestock, plus kitchen and human waste you can meet your cooking and lighting needs easily:

2 gas rings for a couple of hours a day will use between 1-2 m

Gas lights need around 0.1 m3 (100l) per hour.

Driving any kind of engine (eg a generator or a pump) is, however, way beyond the domestic-scale. (Better to go for algal biodiesel!)

What Size Methane Generator is Needed?

If generating methane from manure, collect dung for several days to determine average daily dung production. On this basis, the appropriate size biogas digester plant can be calculated.

For example, where 55 kg of dung a day is available a 8 m3 plant is warranted; where it’s only 6 kg of dung a day, a 1 m3 plant will suffice.

For a family of 8 with a few animals (say 8-10 cows), a 10m digester is a commonly used size in India, with 2 m gas storage.

Ideal Temperatures for Producing Methane from Manure

How long you leave the material in a batch digester depends on temperature (2 weeks at 50C up to 2 months at 15C). The average is around 1 month so gauge how much material you will add each day, and multiply it by 30 to calculate the size of the digester.

While anaerobic digestion occurs between 32 F (0C) and 150 F (65C), the optimum temperature range for methane generating microbial activity is 85F (29C) to 95 F (35C).

Little gas production occurs below 60F (16C). In colder climates placing the digester in a greenhouse, and perhaps using some of the methane to warm the system, are possible strategies.

Methane Generator Systems

Methane Generator Systems

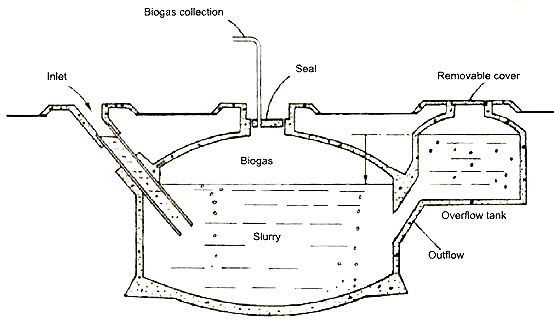

The biogas digesteris the system component where the animal, human and other organic wastes are introduced, usually as a slurry with water, to break down anaerobically.

A storage containeris used to hold the gas produced, from which it is piped for burning as a fuel. Variable volume storage (i.e. flexible bag or floating drum) is easier, cheaper and more energy efficient than high pressure cylinders, regulators or compressors.

When the digester is emptied, the spent effluent is dried for later reuse as a fertilizer.

Types of Biogas Digesters

The two main digester types of digesters are the continuous and the batch. Continuous digesters have a constant throughput of material, and batch digesters extract the gas from a contained batch of material, which is then emptied and a new batch added.

As firewood for cooking has become scarce, millions of small scale continuous digesters are in use in developing countries, especially India and China. Digesters tend to be larger-scale in developed countries, taking animal slurries and human sewage.

Methane Generator Design

The Indian cylindrical pit design has become a popular choice around the world due to its reliability and simplicity. It comprises two basic parts: a slurry tank and a covered by a gas cap or drum to capture the gas released from the slurry.

Domestic Scale Batch Biogas Digestor

Small experimental biogas digester at Redfield.Waste material is put into the oil drum, neoprene cover rises when full of gas, gas is tapped into container (upside-down plastic drum with water seal) which rises as more gas enters.

When full, gas can be tapped off and used with the little gas ring.

Batch digesters based on a container (see photo, above) are feasible on the domestic scale.

Mini Methane Generator Project

Instructions to make a mini methane generator (suit education project) are in the “Methane-Biogas Production Guide” which, along with heaps of other free eBooks on sustainable living, can be accessed free here.

Methane Safety

Like electricity and other energy systems, safety is usually assured so long as the risks are understood and sensible precautions are followed.

Fire or Explosion Risk

Methane is obviously flammable, and can even be explosive. With this in mind…

The methane generator digester area must be well ventilated to prevent the accumulation of trapped gases.

In the vicinity of a digester no naked flames are permitted, electrical equipment must be of suitable quality, normally “explosion proof”, and other sources of sparks are any iron or steel tools or other items, power tools, normal electrical switches, mobile phones and static electricity kept a safe distance away.

A flame trap should be incorporated in the supply line, which must be of a minimum of 20 m long. Instructions on building a flame trap can be found here.

Asphyxiation Risk

Biogas displaces air, reducing the oxygen level so any digester area needs to be well ventilated.

Disease

While the spent slurry has lost a lot of its pathogens, there’s a lot of microbial activity at work in producing biogas energy!

So avoid contact with the digester contents and wash up thoroughly after working around the methane generator (especially before eating or drinking).

Check out this video to see how to make a simple home digester: