Building with Natural and Repurposed Materials

Earthships incorporate many natural and reclaimed materials in their construction. Tires are the perfect form for a rammed-earth brick. There’s no shortage of used tires—at least 2.5 billion are currently stockpiled in the United States, with 2.5 million more discarded every year. Tires can be seen as a globally available “natural resource.” Other materials such as cans and bottles are optional, although bottle brick walls have become an iconic decorative feature of many Earthships. All interior walls are packed out between the tires and plastered with adobe mud. Mud can also be used for floors, and reclaimed wood and metal are often used.

“But what about tire off-gassing?”

(An extensive study by the University of Wisconsin-Madison that was presented to us by the state of New Mexico.)

Materials Awareness

Structure = Walls. Walls are made of materials. The major materials presently used for housing compartments have many factors that warrant some rethinking.

1. Too much wood is used and although this is a renewable source, trees need time to grow. Wood is weak, it rots, burns and molds.

2. Many materials are made in centralized areas and have to be shipped very far. This is an economic and an energy factor. This is an embodied energy factor. Results in a much higher carbon footprint.

3. Most materials require specific skills to use them. This renders them out of the reach of unskilled people to use.

4. There is tremendous energy involved in the manufacturing of materials and consequently unacceptable pollution levels as a result.

5. Many new materials are unhealthy to be around. Unfortunately, this is not discovered until they have been used for years.

6. Manufactured materials tend to dictate the nature of housing. Building performance should dictate the nature of construction materials. Performance both during construction and during the lifetime of the building.

Tire Walls

Structural, Bearing and Retaining Walls made with rammed earth encased in recycled steel-belted rubber tires. Very strong, Economical, Local, Sustainable.

The major structural building component is recycled automobile tires filled with compacted earth to form a rammed earth brick encased in steel belted rubber. This brick and the resulting bearing walls it forms is virtually indestructible.

The tire is used as found without any modification. The process of ramming them full of densely packed earth is achieved with simple human labor and can be done with whatever type of earth is available on the building site.

Common people of all shapes and sizes can easily learn to gather tires and pack them full of earth with simple hand tools and with the same type of human energy used while trying to tone up their bodies in the local gym.

The impact of large scale use of this idea would result in depletion of the giant tire mountains that have become a serious problem in many cities. This building block is therefore achieved with little additional energy.

Thermal Mass

There are few materials of any kind that would provide better, more dense mass for storing

temperature than rammed earth. The rubber tire casings provide a natural form for humanly manageable production of thermal mass building blocks with little more than human energy. There are also very few materials that would provide the structural bearing capacities and homogeneous qualities of an earth rammed tire wall. The diameter of the tires (2’-4″) sets the thickness for the walls of the building. This amount of dense mass surrounding every room provides a thermal battery that helps to keep the building comfortable with no fossil fuels.

Durability

The durability of tires filled with earth can not be surpassed. A buried tire (which is in effect

what we have in a tire wall) will virtually last forever. The only thing that deteriorates rubber tires is sunlight or fire. Since they are filled with earth and ultimately covered with earth and concrete plastered over, they never see sunlight. Tires only burn when surrounded by air. When they are filled and coated with earth and concrete plaster, trying to get them to burn would be like trying to light a phonebook on fire as compared to a wad of paper. The very qualities of tires that makes them a problem to society (the fact that they won’t go away) makes them an ideal durable building material. Earth and tires by virtue of their very nature will last forever.

Resilient

Whereas a rammed earth tire wall is amazingly strong, it is obviously not brittle. It can vibrate or move without fracture or failure. Since these walls are so wide and the loading on them is widely distributed, the entire structure would have the potential of absorbing and moving with a considerable horizontal shock from an earthquake. There is probably no other material available at any price that has the reliance that earth rammed tires would have.

Low specific skill requirements

Over the past 40 years many people of all shapes and sizes have been taught to “pound tires” (the term used for the process of densely packing the tires with earth). Within one or two hours the average human can be an expert. It requires physical energy more than brute strength.

A team of two people, one shoveling and one pounding, can pound about four tires an hour. The shoveling job is easiest while the pounding requires a little more strength and energy. The general application of common human capabilities is definitely all that is required here. This is a skill that the very lowest people on the labor force can become good at.

Low tech

The only real major piece of equipment needed to build a tire building is a backhoe. This is a common piece of equipment needed for all buildings of any type. Backhoes and operators rent almost anywhere for 30 to 50 dollars per hour. Other typical tools needed are a chain saw, circular saw, and a cement mixer. Common people use these tools all the time and they are very easily accessible to all.

Can & Bottle Walls

A can wall is a wall constructed from recycled aluminum cans, which are not a common building source. The cans can be laid in concrete, similar to bricks to make all kinds of strong walls and other partitions

Cans can form the actual fill-in structure (or walls) of a building, as is done with earthships.

This is a building construction style which usually uses glass bottles (although mason jars, glass jugs, and other glass containers may be used also) as masonry units and binds them using adobe, sand, cement, stucco, clay, plaster, foam, mortar or any other joint compound. This results in an intriguing stained-glass like wall.

Insulation

Thermal insulation is the reduction of heat transfer (the transfer of thermal energy between objects of differing temperature) between objects in thermal contact or in range of radiative influence.

Thermal insulation in buildings is an important factor to achieving comfort. Insulation reduces unwanted heat loss or heat gain and can decrease the energy demands of heating and cooling systems. Thermal Insulation does not necessarily deal with issues of adequate ventilation and may or may not affect the level of sound insulation. In general, “the more insulation the better” is a good principle to start with.

There is, of course, a limit to how much should be used. The law of diminishing returns says that every time you double the amount of insulation, you cut the heat loss in half. This is great the first few times as the heat loss goes from 1 to 1⁄2 to 1⁄4, etc. Unfortunately, the cost keeps up with the thickness of insulation, while the heat loss decreases by ever smaller amounts (e.g., from 1∕32 to 1∕64 to 1∕128, etc.). However, this simplistic approach to building economics has done much damage. A more realistic approach is to see how the cost of the whole building changes as more insulation is used. As Amory Lovins says, “You can tunnel through the cost barrier.” As more insulation is used, the heating and cooling systems get smaller and less expensive. In many climates, super-insulation can eliminate the heating system altogether, and in some climates it also eliminates the cooling system. Large amounts of insulation can be less expensive than small amounts even for the initial costs.

Large amounts of insulation also provide a passive security system. When there is a power failure in the winter in a super-insulated building, the temperature indoors will drop less, and more slowly, than in a conventional building. It is surprising that in a world where people crave security, they don’t make their homes more secure. However, there is growing interest in making our buildings and communities more resilient by the way they are designed and built. Furthermore, since future energy sup- plies and cost are uncertain, it is wise to be conservative and to use as much insulation as possible.

Insulation goes everywhere so there are no gaps anywhere.

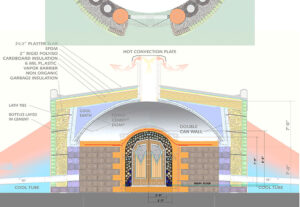

Most conventional buildings only use insulation and do not use thermal mass. All buildings should use both insulation and thermal mass. Thermal Mass on the inside of the wall and insulation on the outside of the wall. See below ‘The Perfect Wall’.

The effectiveness of insulation is evaluated by its R-value, of which there are two – metric (SI) and US customary, the former being 0.176 times the latter. For attics, it is recommended that it should be at least R-38 (US customary, R-6.7 metric). However, an R-value does not take into account the quality of construction or local environmental factors for each building. Construction quality issues include inadequate vapor barriers, and problems with draft-proofing. In addition, the properties and density of the insulation material itself is critical.

Types of Insulation

- Batts & Blankets

- Fiberglass

- Plastic Fiber Insulation

- Natural Fiber Insulation Material

- Cotton

- Sheep’s Wool

- Straw

- Hemp

- Polystyrene Insulation

- Polyisocyanurate

- Polyurethane

- Vermiculite / Perlite

- Urea Formaldehyde

- Cementitious

- Phenolic Foam

- Mineral Wool

- Dry Cellulose

- Cellulose

Indigenous

Materials are found all over the planet. Shipping materials for long distances is not sustainable and uses excessive amounts of energy. In order for affordable housing to be easily accessible to the common person and to maintain a low impact on the planetary energy situation, a “building block” found all over the globe would be required.

Organize Materials & Components

Organize the materials and components so they are accessible by when they will be used. Tire pounding tools, cardboard, etc. would be upfront, whereas the faucets and paint and furniture can be in the back. As with the tools, make sure all materials are stacked safely and covered to protect from the weather and elements.

Materials and components needed for each building are different per building. To properly build and execute the plan and schedule for a building, all materials must be available without delay. Acquiring all materials and having them available and ready is critical to the success of the build.

By cutting down on time spent setting up and breaking down a jobsite, you can save money and increase productivity. The biggest time wasters include choosing and transporting tools to and from the truck, setting up and breaking down the work area, and cleaning up dust and debris. Creating a system for handling these tasks can save time and enhance your reputation with clients as an organized professional.

There’s really no secret in how to become more efficient: You need to choose a system and put it in place. The hard part is being disciplined about using it. While this requires a bit of upfront effort, it offers measurable payoffs.